Request a quote

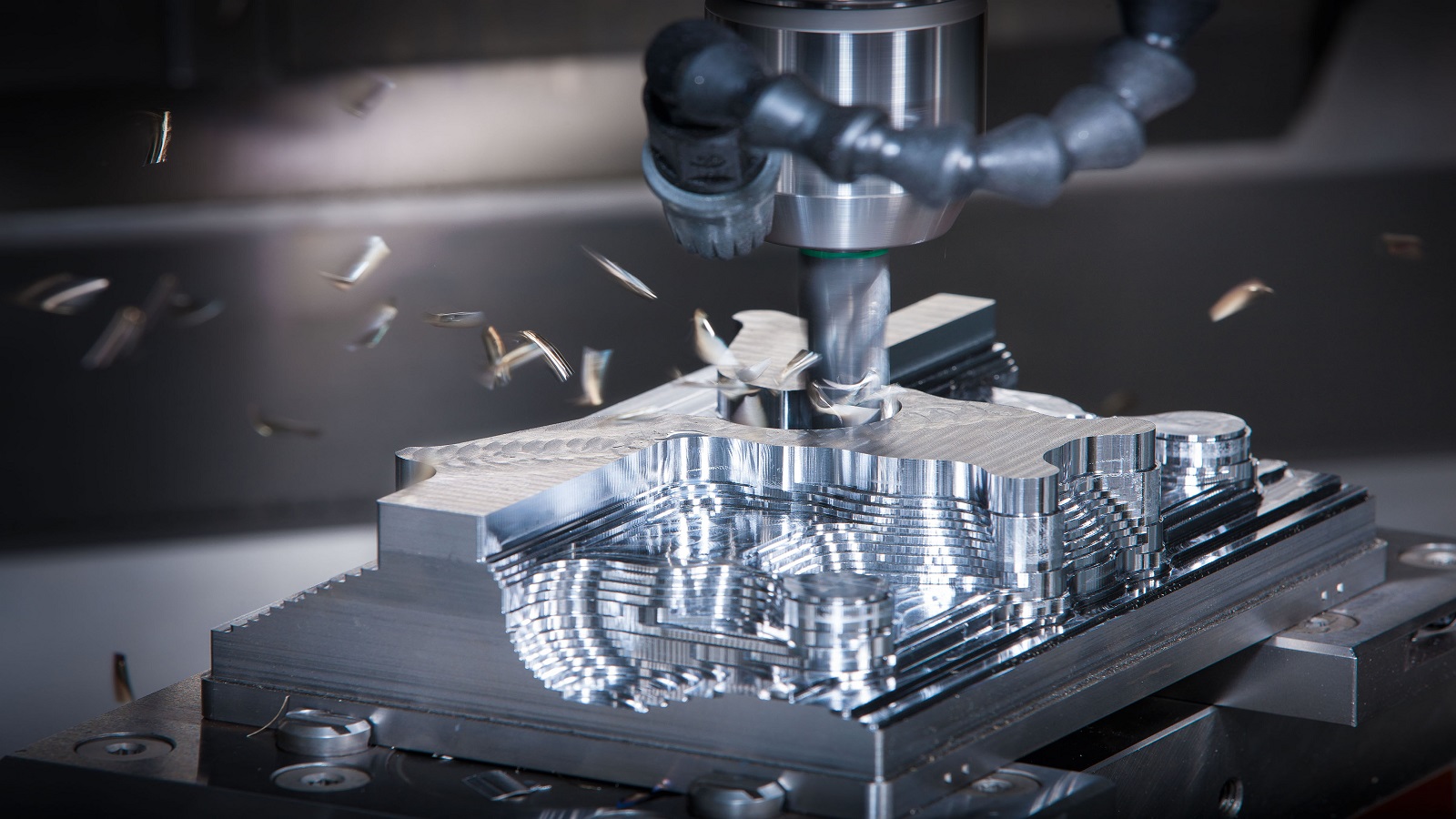

Materials used in Maysea CNC Milling:

Metal:

Carbon Steel - 1018, 1045 Stainless Steel -03,304,316 etc.,

Copper & Brass UNS C36000 etc.,

Aluminum 6061 T6, 6063 T6 etc.,

Non-Metal: Plastics like Peek, POM etc.,

Max Size : Length X Width X Hight =

102 inches (2600mm) X 31 inches (800mm)X 31 inches(800mm)

Maysea support both High Volume and HMLV business model, provide competitive prices.

Lot Size Can be 1 pcs to 1000K pcs