Request a quote

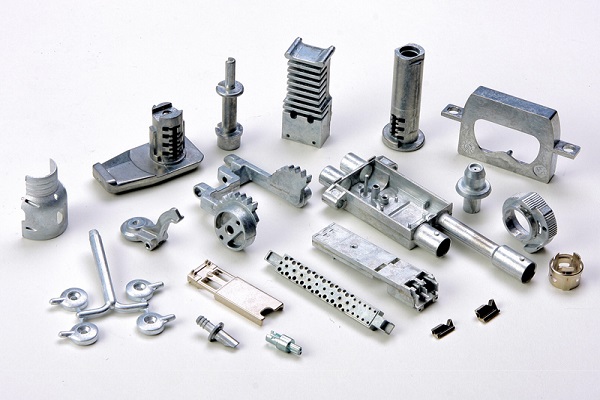

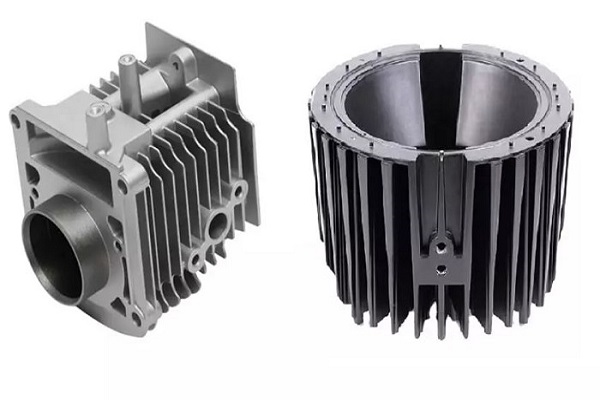

Zinc Alloy: ZAMAK 3, ZAMAK5,ZAMAK2.

Aluminum: ADC12, A380, A356 etc.,

Brass Alloy specified by customers

Parts Weight from 0.01 kg to 100kgs

Maysea support both High Volume and HMLV business model, provide competitive prices.

Lot Size Can be 1 pcs to 1000K pcs