Request a quote

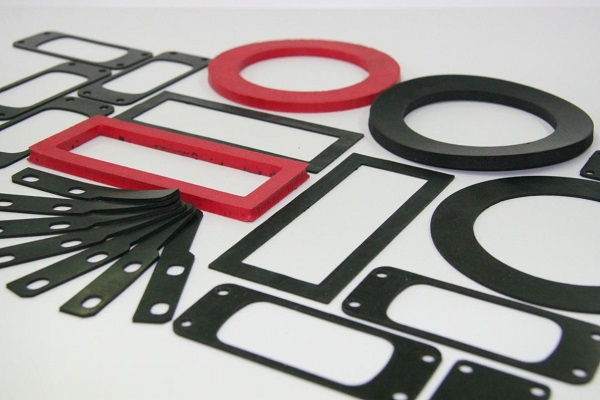

Sealing Parts, O-Ring, Oil Seals, Gasket

Customized Molded Rubber Parts

Rubber-Metal Parts

NR, CR, NBR,

FKM, EPDM, ACM, HNBR,

AEM, Si

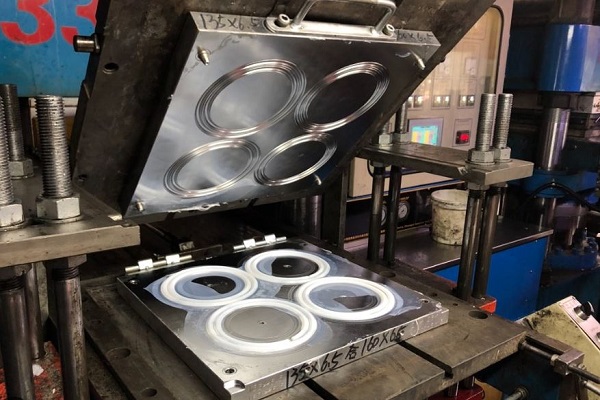

Sealing Parts, O-Ring, Oil Seals, Gasket - vulcanization line

63T/100T/200T/250T/300T/500T Vacuum Machines

Rubber-metal parts vulcanization line

80T/200T/300T/580T Vacuum Injection Machines

Maysea support both High Volume and HMLV business model, provide competitive prices.

Lot Size Can be 1 pcs to 1000K pcs