Request a quote

EPDM Rubber & Sponge

Neoprene Rubber & Sponge

Silicone Rubber & Sponge

Viton® Rubber

Red Rubber

Pure Gum Natural Rubber

Cloth Inserted Rubber

Diaphragm Sheet

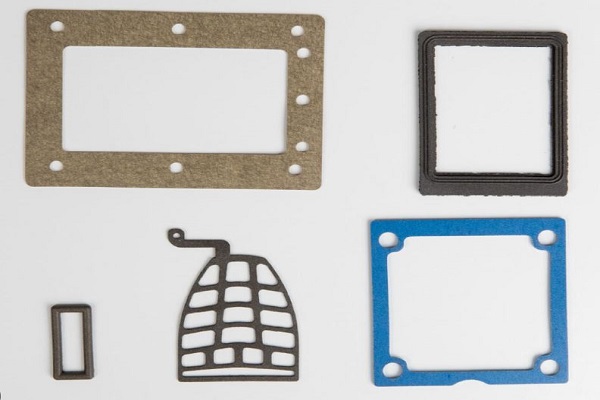

FishPaper

Garlock Sheet

Vellumoid (Vegetable Fiber)

Cork, Cork & Rubber

SAE Industrial Felt Product

When choosing the gasket thickness for compressed materials, remember that thinner is better. Most compressed sheet gasketing sealing values are based on 1/16” thickness. Thicker materials require a greater compressive force to seal and have lower pressure ratings. The use of 1/16” thick gaskets will provide better sealing with lower bolt loading than 1/8” thick gaskets. So thinner is usually not only more cost effective, Thinner works better!

Maysea support both High Volume and HMLV business model, provide competitive prices.

Lot Size Can be 1 pcs to 1000K pcs